Swarm Intelligence and Combinatorial Optimization for Energy Efficient and Adaptive Industry 4.0

The video material is provided by ORF.

Motivation

Climate goals, rising energy, resource demand and a history of supply difficulty, motivate the identification of energy and resource efficiency potentials as one of the main priorities of the industrial sector in the near future. A sustainable Industry 4.0 and cyber-physical manufacturing systems not only enable real-time interaction, machine-learning (artificial intelligence) and eased monitoring, they are also conceived as potentially energy and resource efficiency-enhancing based on their ability to provide real-time data via computation on the edge. A high mixture of product diversity together with historical growth of the industrial plant further induce complexity leading to an NP-hard scheduling task. In the current exemplary situation of a semiconductor plant, multiple machines need to be scheduled (between 400 and 1.200 different stations). They typically produce more than 1.500 different products in around 300 different process steps. Linear optimization methods cannot cope with the highly complex, large, and dynamic search space due to excessive computation time. These methods can only be used on a subset of the plant, do not consider the entire system behavior, and thus, do not exploit the optimization potential.

SwarmIn Goals

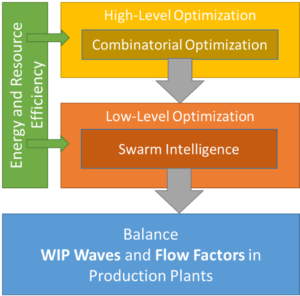

In SwarmIn the overall goal is to balance WIP waves and flow factors along with production plant optimization featured with energy- and resource-efficiency parameters. To reach this goal we design a new architecture to combine different methods of aritificial intelligence (AI) in an advantageous way: first, we apply combinatorial optimization as a high-level optimization approach for a global estimation of configuration parameters. It reduces the solution space that is used as input for the second, low-level optimization applying swarm intelligence as a multi-agent, bottom-up approach. This is an innovation, as a mixed-swarm approach that considers both cyber-physical systems (CPSs, e.g., machines, lots) and humans as agents impacting energy and resource efficiency in an Industry 4.0 setting has not been investigated in the field of semiconductor manufacturing before. In the low-level optimization, each agent is equipped with a set of local rules. The connection between high- and low-level optimization is a novelty, for which we model the production plant as a self-organizing system of agents that work together.

Low-level optimization based on swarm intelligence (which is a subfield of AI) is performed locally (on machines/lots, close to the process), whereas the high-level optimization (combinatorial optimization) is done centrally, e.g., as a cloud-based service closely connected to a factory-ERP system. Both levels strongly interact with means of (wireless) communication where 5G can be the technology to provide Industry 4.0 requirements in terms of latency and reliability. Additionally, parameters to measure energy and resource efficiency via retrofit sensors in the production process and feedback from human actors are identified. Beside the analysis of these parameters, one innovation is to include them into high- and low-level optimization to produce energy- and resource-based reactive behavior for CPS and human(-machine) interaction in the production process. The overall result of SwarmIn will be algorithms and simulations for high- and low-level optimization to cope with the high complexity of production in Industry 4.0 and with energy- and resource-efficiency requirements in the form of a software library. In

contrast to other projects in this field, SwarmIn builds a radically new architecture to combine different AI approaches for the first time (combinatorial optimization and swarm intelligence) according to their advantages. Additionally to that, the SwarmIn architecture includes humans as swarm members as well as resource and energy efficiency as another dimension for the optimization of a sustainable production plant of the future.

Consortium and Contact

Project Coordinator:

Lakeside Labs GmbH

Melanie Schranz

Lakeside Labs B04b

9020 Klagenfurt

Project Partner:

Infineon Technologies Austria AG

Walter Laure

Siemensstraße 2

9500 Villach

Novunex GmbH

Andreas Wuttei

Völkermarkter Ring 7

9020 Klagenfurt

University of Klagenfurt

Martin Gebser

Universitätsstraße 65-67

9020 Klagenfurt

Universität Graz

Nina Hampl

Institut für Umweltsystemwissenschaften

Merangasse 18/EG

8010 Graz

Messfeld GmbH

Michèle Posch

Lakeside B07a

9020 Klagenfurt

The project is funded by FFG and BMK “Production of the Future” under contract number 894072.